Now that the MC4 project reaches its final year of implementation, it’s time to dive into the recycling methods that are being developed.

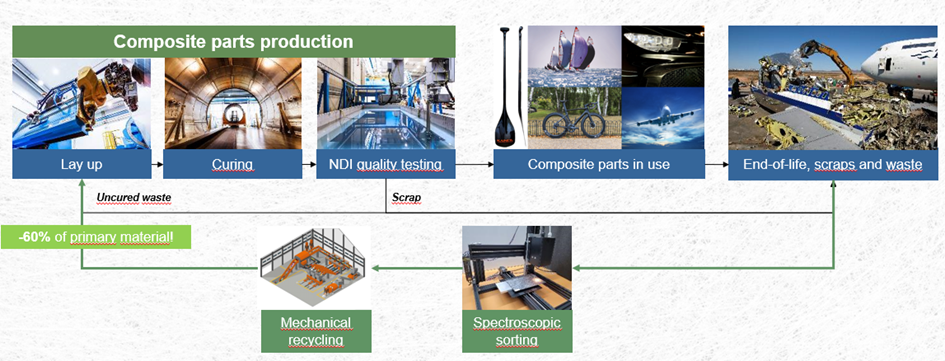

For the short-term recycling method of glass fibre composites, the idea is to perform a mechanical recycling of the composites by collecting scraps at different steps of its lifespan. The uncured composite waste will be recovered after the lay-up step, then the scrap from the quality testing will be recuperated. Finally, the end-of-life scrap will be collected and all the waste gathered at each step will be sorted thanks to a spectrophotometer and mechanically recycled. The recycling process doesn’t separate the matrix from the reinforcement but shreds the entire composite material and allows to obtain a chip. The idea after is to reuse this shredded material as a filler in new composites.

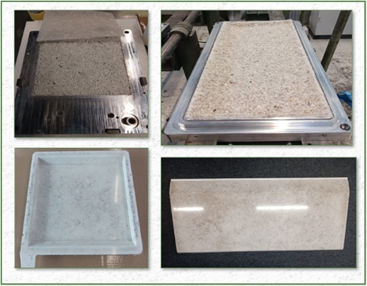

The current state of play is the creation of a bus side skirt made of scrap bus side skirt. The shredded composite material was mixed with virgin glass fibres to form the interior of the structure. The virgin glass fibre came from the leftover fabrics from the lay-up process. Then, epoxy resin was added, the reason why the resin was in a foam form was to allow it to penetrate well into the mixture of virgin fibres and shredded material. For the exterior, non-woven made of glass fibres were used to ensure good mechanical properties and a good visual appearance. For this process, the company Circular Recycling Company (CRC) did the shredding and VDL fibertec industries received the shredded composite and produced the new bus side skirt.

“Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.”